Old MacDonald has a farm, and on that farm he has some chicks and goats. But MacDonald's animals are not there to be eaten. They are highly specialized production units - the results of many years of scientific work, and extremely costly.

Yes, they look just like any other chicken or goat. They behave and act exactly like their forefathers, but in fact they are living factories of proteins and enzymes too complex to be manufactured by traditional chemistry. The animals have been genetically engineered in ways that make their cells generate the complex molecules. These precious compounds can then be extracted from the eggs or milk - and can be added as an ingredient in one of the countless new medical treatments that have been developed since genetic research gained serious momentum.

To Old MacDonald it was a major changeover from one type of farming to another. It is no longer a matter of producing large volumes of cheap crops. Now, he is a supplier of highly specialized, top-quality products and consistent, documented trustworthiness is the keyword. His farm produces less than 20 kilos of protein a year - which is already more than most other farms. Nonetheless, his financial situation is better now than ever before.

MacDonald's younger brother, Allan, is also a farmer. He produces meat - or rather, something very much like meat. As a young man, Allan wanted to be a farmer like his father before him, but he could not put up with the poor reputation that traditional farming had acquired - especially not that of large-scale pig producers such as his father. Water pollution, the smell and not least the constant animal welfare scandals, medication, etc. were not what he wanted his farm to be associated with.

Around 2015, scientists had developed the field of human tissue production to the point of being an established and relatively common method of treatment. Starting with only a few cells, entire cell cultures could now be grown into skin, cartilage, membranes and, increasingly, into entire new organs like livers or kidneys. Using cells from the patient, who would eventually have the tissue re-operated into his own body, scientists could be sure that the cell type would be a perfect match thereby preventing the patient's immune system from destroying any foreign tissue.

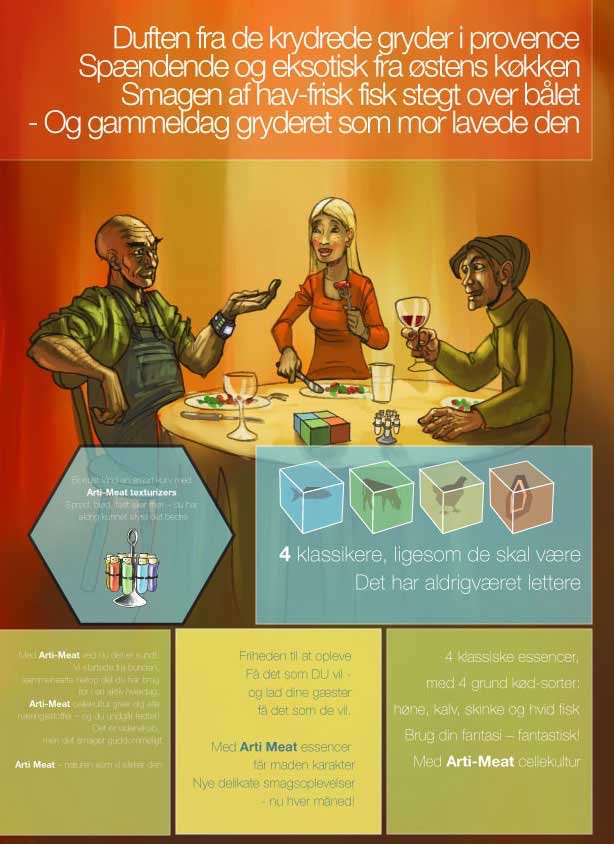

Once the health authorities had approved this type of treatment, it was obvious to proceed using the technique to produce animal tissue for use in the food industry. This lead to a dramatic change in terms of cooking and food preparation - comparable in scope to what happened when potatoes, tomatoes and corn were first brought to Europe from the then newly discovered Americas.

Today, the meat on most dinner tables is artificially made. If you want a good old-fashioned, juicy steak you'll still have to pay for the real thing, though. Scientists are still faced with the problem of growing large volumes of solid muscle tissue. They have not yet managed to make blood vessels sprout and support large chunks of muscle in a manner suitable for profitable mass-production.

In most traditional recipes, however, that is not a problem - small lumps of muscle fibers are perfectly okay in meatballs, spaghetti sauce, hamburgers, sausages, etc. As far as inexpensive convenience foods are concerned, most consumers wouldn't be able to tell the difference from artificial and real meat - and only very few are willing to pay the difference.

As far as fish is concerned, artificial meat is basically the only option left for everyday cooking. It will be another 15 years before the first fishing quota will be granted following the global ban on industrial fishing introduced in 2022. Marine biologists still have their doubts as to which species of fish will be sufficiently reconstituted at that time to allow large-scale industrial fishing again.

Schizophrenic Gastronomy

The advantages of artificial meat are obvious. As Allan MacDonald likes to say: “The shift to producing artificial meat was like changing from being part of the problem to becoming part of the solution”.

There is hardly any pollution, and financially, it is a far more lucrative method of production. Producing a single kilo meat from a living cow requires an input of 4-10 times as many calories in terms of feeding stuff. In the production of artificial meat, however, everything is reprocessed into muscle fibers. So it's an easy choice, price-wise and morally - in a world with 8.5 billion mouths to feed.

Also, no animal will suffer when we eat artificial meat. Many vegetarians do not hesitate to eat the artificial meat - because it was never part of a living, breathing creature.

In recent years, a slightly controversial dietary belief has emerged - cannibalism. It started out as an artistic provocation on the part of Devdas Aiyat from India, who declared that he would never again eat artificial meat that was not grown from his own cells. Much to his surprise, the idea won widespread acceptance and today you can find small “self-eater” societies in most countries with members claiming that meat from their own cells is the perfect diet to satisfy their nutritional needs.

Basically, artificial meat tastes - almost - exactly like the cells from a living animal. Making meals interesting does require a few additions, however - but they come in plenty today.

At the start of the millennium, most ordinary dinner tables would offer nothing more than salt and pepper for spices. Today, we see af rapidly growing selection of flavoring agents allowing us to adjust the taste, texture and crispness of the fibers to our own personal liking. Despite the solid sales, we have probably only seen the tip of the iceberg of this new market. Every week sees the introduction of new flavors, new theme-mixed additives, etc. which the news media reviewers will invariably analyze and appraise. It is in the preparation of the artificial food fibers that present day chefs prove their worth.

In a recent article on the “Food and People” website, leading food columnist, Anne-Marie Niçois, commented on our paradoxical relation to foodstuffs. In the article headed “Schizo-food”, she describes how, on one hand, we eat artificial meat, genetically manipulated taste additives as well as fruits and vegetables that have been changed beyond recognition by means of bio-technologies to be highly productive and cheaply produced. We eat functional foods, as much for their medical or cosmetic effect as for their good taste. But, on the other hand, for the very same meal, we demand raw materials that are completely original. On special occasions, when we really want a gastronomical experience, we choose meat from a real cow or chicken that grew up on a small, preferably almost historical farm, and we want vegetables in which not a single letter has been manipulated in its genes.

This oldfashioned segment is by no means a small, insignificant niche production. Anne-Marie Niçois estimates that about one sixth of the food production is “original”, even if, she points out, that kind of production typically takes place in sealed greenhouses to prevent cross-breading with genetically manipulated strains.

Niçois concludes that we buy original foods to stay in touch with something original and natural. But, ironically, the many precautions taken to shield, document and stage the original foodstuffs, mean that they are no longer any less advanced from a technological point of view than any other kind present day foodstuff.

Hi-tech Farming

As from 2010, both European and American farmers were suddenly faced with the harsh facts of life in a global reality. Within a decade, the huge agricultural support systems were largely phased out, and farmers were forced into direct competition with their counterparts in the developing countries. As in so many other industries, the solution to move forward was focusing on specialization and extreme streamlining of the production.

The name of the game is being able to supply fibers with the characteristics most in demand at any given moment. Depending on the type of cell culture chosen, the contents of fat, cholesterol, minerals, etc. can be precisely controlled. A wide variety of genes producing specific proteins can be added to contribute with each their special taste, flavor or medical effect. The process, however, requires flexibility and not least an intense and ongoing development effort. Therefore, farmers typically cooperate closely with a larger corporation that can finance the research and which buys most of the farm's output of proteins or fibers up front. For more than six years, Allan MacDonald has cooperated with the North European market leader, Baltic Food Fibers.

Looking back, the fundamentals of farming and the toils of the farmer have changed radically during the past years. There is still a fair amount of old-fashioned hard work, but robot tractors and harvesters have largely taken over the field work. Farming has become more of an intellectual effort. To keep up with the new technologies, farmers must constantly attend post-educational training sessions. Running a farm requires no small amount of competencies: electronics, biology, quality control, process management, etc.

Currently, Allan MacDonald operates three production lines: chicken, beef and fish.

The production processes are basically identical. The fibers grow in huge, flat steel vessels with the specific cell culture. Nutrients are added and the temperature is kept at 37 degrees centigrade. After a few weeks, the fibers are harvested and the process starts all over again.

The nutrients mostly consist of carbohydrates, first of all sugar which Allan MacDonald extracts from the crops growing on his fields. This year it's primarily corn.

The corn has been genetically manipulated to have a high sugar content and new genes have been added that enhance its resistance to insects and rot. The edible parts of the plant are processed and refined into a thick fluid from which the artificial meat will eventually grow.

The rest of the plant and the ooze from the production of the nutrient fluids go into another complex system of steel tanks where specially developed enzymes process the substance into Allan MacDonald's second-most important product, methanol.

Just like Allan had never imagined that he would become a producer of fish meat, he had never expected to become a supplier of energy. But - biotechnology has fundamentally re-defined the concept of farming.

As we all know, only a small part of our plants can be used for food. Most of the plant is stems and leaves or residues from the oil press or the processing of cereals and vegetables. In the old days, the disposal of such plant residue was a problem, but in today's processing plants, enzymes can turn more or less the entire energy contents of the substance into liquid bio-fuel.

To the farmers, this development is a highly appreciated new source of income and to society, it was a welcome new alternative source of energy in times where oil prices skyrocketed and the use of fossil fuels such as oil, gas and coal were increasingly restricted as the results of the greenhouse effect became evident.

Bio-fuels offered a CO2-neutral alternative to gasoline and fuel oil as the carbon dioxides released in the process of burning bio-fuels are identical to what the plants absorb while they grow.

The Post-Oil Times

Only some 30 years ago, most of our household heating and electricity were produced by huge central power plants and largely all forms of transportation were fuelled by gasoline. Oil and gas were extremely cheap, and we had not yet understood the need for a drastic reduction of carbon dioxide exissions into the atmosphere.

Today, mineral oil is largely history, and gas and coal power plants are a dwindling part of an ever-growing choice of energy sources - almost all of them renewable.

When Old MacDonald looks at the sea, he can occasionally catch a glimpse of the distant windmill park. It is located more than 45 km off the shore, but the mills are very tall. It is thanks to the nano-technological headways made during the past years that the wings can now have a span of more than 200 m. It is only by constructing the materials from the molecular level up that the strength and lightness required to withhold the enormous pressures at sea can be obtained.

The periods of production of electricity from the mills does not necessarily match the periods of demand for electricity - just as the huge wave-energy installations and countless small and big solar panels do not necessarily contribute the most at the exact same time that society requires electricity.

Even before the turn of the century, it was clear that hydrogen would come to have a key role in the future power supply systems as hydrogen is a means to storing energy - making it possible to counterbalance fluctuations in the production of electricity coming from the wind, the sun and the waves.

In times of plenty, electricity is used to separate water into oxygen and hydrogen. The hydrogen is stored and whenever demand outweighs the output from the renewable sources of energy, the hydrogen will be passed through fuel cells to produce electricity.

Today's power supply is characterized by a wide range of alternatives. In some areas, hydrogen is supplied via pipes to the individual households in order that they can produce both heat and electricity by means of the fuel cell unit that has replaced the traditional oil or gas furnaces. Elsewhere, energy is “harvested” locally, for instance by windmills, and stored as hydrogen which can easily be converted into electricity and enter the supply lines during hours of peak demand in electricity.

Also, most cars have their own fuel cell - some will use hydrogen, others methanol. Many of the new fuel cells for cars can use both.

The end of the oil age was not just about energy. Up until about 20 years ago, plastic was usually made from oil. Since the 2020's, bio-plastics and the many other new plant-based fibers have increasingly taken over the role of the old-fashioned plastics. Once again, we owe the changes in what we can grow to bio-technological advances. Not only is bio-plastic largely just as good as any plastic based on mineral oil - the pollution is practically non-existent, and there is hardly any waste from the production process. Bio-plastic is usually biodegradable or combustible and can be used in the production of energy.

Jack Rahnt, a social historian, has studied the fundamental changes that have taken place in relation to the planet's natural resources. He explains the logic behind the change as one that originates back in the early industrialization of the 1800's. At that time, machines set the human race free from the limitations of nature. But machines are linear: they extract rare resources, consume them and throw them away as waste.

“In the clear light of hindsight, the process was incredibly inefficient, but the system did in fact work well until resources became scarce and the problems with waste and discharges became unacceptable”, says Rahnt.

It is very telling that the president of the EU, Francesca Federali, in her inauguration speech pointed to the fact that “recycling is not only the basis for maintaining and increasing our wealth, it is fundamental to our survival”.

Looking back, we might say that the oil-age was merely a parenthesis in the history of mankind, where most of both the energy and the materials we used originated in matters totally unrelated with the processes that take place on the surface of the earth. Now we are rapidly returning to energies and materials that are part of the endless circle of life.

Text: Peter Hesseldahl